Electromagnetic compatibility (EMC) constraints in the design and integration of on-board systems are essential to ensure the proper functioning of your equipment. Natural or industrial, electromagnetic disturbances are numerous and make the automotive industry a demanding industry with major environmental and electromagnetic constraints. GETELEC provides the automotive industry with its technical know-how and specialised products in order to offer the most reliable and advanced solutions on the market.

On-board systems in the automotive industry today contain a large proportion of electronic components that can be subject to significant electromagnetic disturbances that can lead to major malfunctions throughout the system. These constraints are all design challenges that GETELEC meets through its dedicated EMC shielding conductive silicone range.

GETELEC’s technical teams support design offices from the initial design choices to the final implementation.

Thermal management of electric and hybrid vehicles is an essential element in ensuring the efficiency and durability of batteries. Our range of thermally conductive pads ensures high-performance thermal dissipation and conductivity for your equipment.

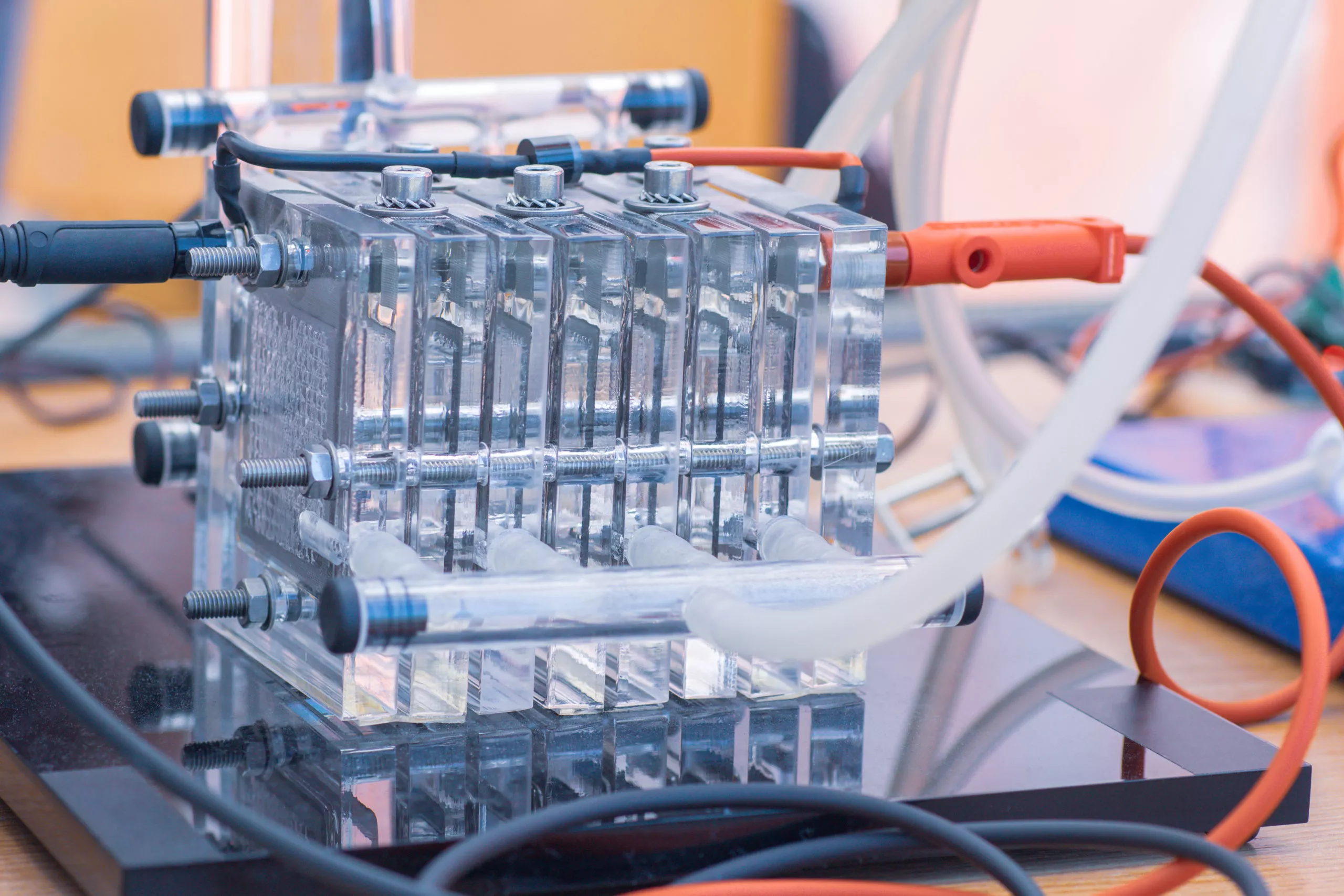

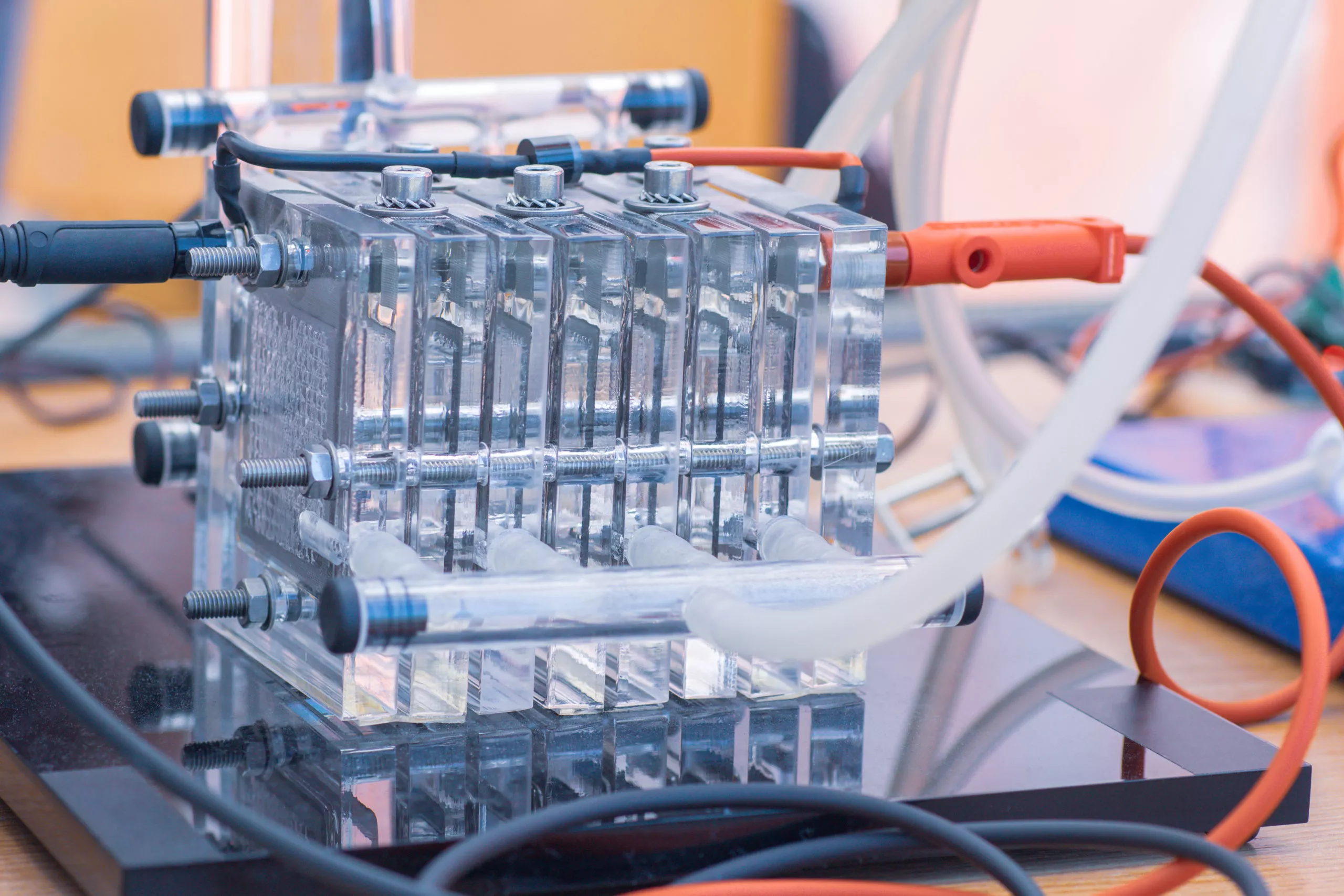

The membrane electrode assembly (also called MEA) includes technical environmental sealing silicone seals. Their purpose is to control the compression that will guarantee the tightness of the cell and the reliability of the contact (electrical, fluid and thermal) between the various materials making up the cell core. GETELEC’s experience in the field of high-performance elastomers has enabled us to design seals for PEM (Proton Exchange Membrane) fuel cell stacks

The bespoke development of our products allows you to benefit from the most durable and innovative solutions on the market.

Our expertise in the design of elastomer compounds and our teams of dedicated engineers allow you to benefit from personalized turnkey support for your project and the development of a bespoke solution that meets all of your constraints.

Our different manufacturing methods allow you to benefit from the latest generation equipment with multiple possibilities for a reliable, efficient product that meets your requirements