Page 108 - GETELEC - Products and solutions Catalog

P. 108

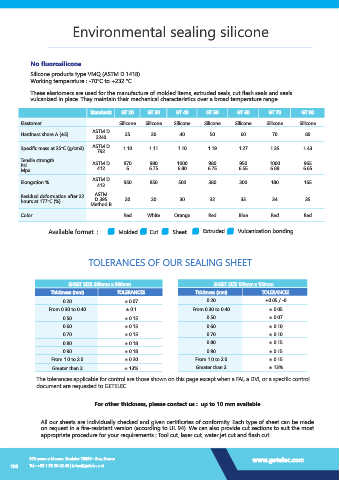

Environmental sealing silicone

No fluorosilicone

Silicone products type VMQ (ASTM D 1418)

Working temperature : -70°C to +232 °C

These elastomers are used for the manufacture of molded items, extruded seals, cut flash seals and seals

vulcanized in place. Thay maintain their mechanical characteristics over a broad temperature range.

Standards GT 20 GT 30 GT 40 GT 50 GT 60 GT 70 GT 80

Elastomer Silicone Silicone Silicone Silicone Silicone Silicone Silicone

Hardness shore A (±5) ASTM D 25 30 40 50 60 70 80

2240

Specific mass at 25°C (g/cm3) ASTM D 1.10 1.11 1.10 1.19 1.27 1.35 1.43

792

Tensile strength ASTM D 870 980 1000 980 950 1000 965

Psi 412 6 6.75 6.80 6.75 6.55 6.89 6.65

Mpa

Elongation % ASTM D 950 850 500 380 300 180 165

412

Residual deformation after 22 ASTM

hours at 177°C (%) D 395 20 20 30 32 33 34 35

Method B

Color Red White Orange Red Blue Red Red

Available format : Molded Cut Sheet Extruded Vulcanization bonding

TOLERANCES OF OUR SEALING SHEET

SHEET SIZE 300mm x 300mm SHEET SIZE 150mm x 150mm

Thickness (mm) TOLERANCES Thickness (mm) TOLERANCES

0.20 ± 0.07 0.20 +0.05 / -0

From 0.30 to 0.40 ± 0.1 From 0.30 to 0.40 ± 0.05

0.50 ± 0.15 0.50 ± 0.07

0.60 ± 0.15 0.60 ± 0.10

0.70 ± 0.15 0.70 ± 0.10

0.80 ± 0.18 0.80 ± 0.15

0.90 ± 0.18 0.90 ± 0.15

From 1.0 to 2.0 ± 0.20 From 1.0 to 2.0 ± 0.15

Greater than 2 ± 13% Greater than 2 ± 13%

The tolerances applicable for control are those shown on this page except when a FAI, a DVI, or a specific control

document are requested to GETELEC.

For other thickness, please contact us : up to 10 mm available

All our sheets are individually checked and given certificates of conformity. Each type of sheet can be made

on request in a fire-resistant version (according to UL 94). We can also provide cut sections to suit the most

appropriate procedure for your requirements : Tool cut, laser cut, water jet cut and flash cut.

375 avenue Morane Saulnier 78530 - Buc, France www.getelec.com

108 Tel : +33 1 39 20 42 42 | infos@getelec.net