Our GT70 elastomer materials with a hardness of 70Shore A have been developed for applications requiring excellent fire resistance. Compliant with the requirements of the Boeing FAR25.853 and Airbus ABD0031 standards, the parts obtained benefit from:

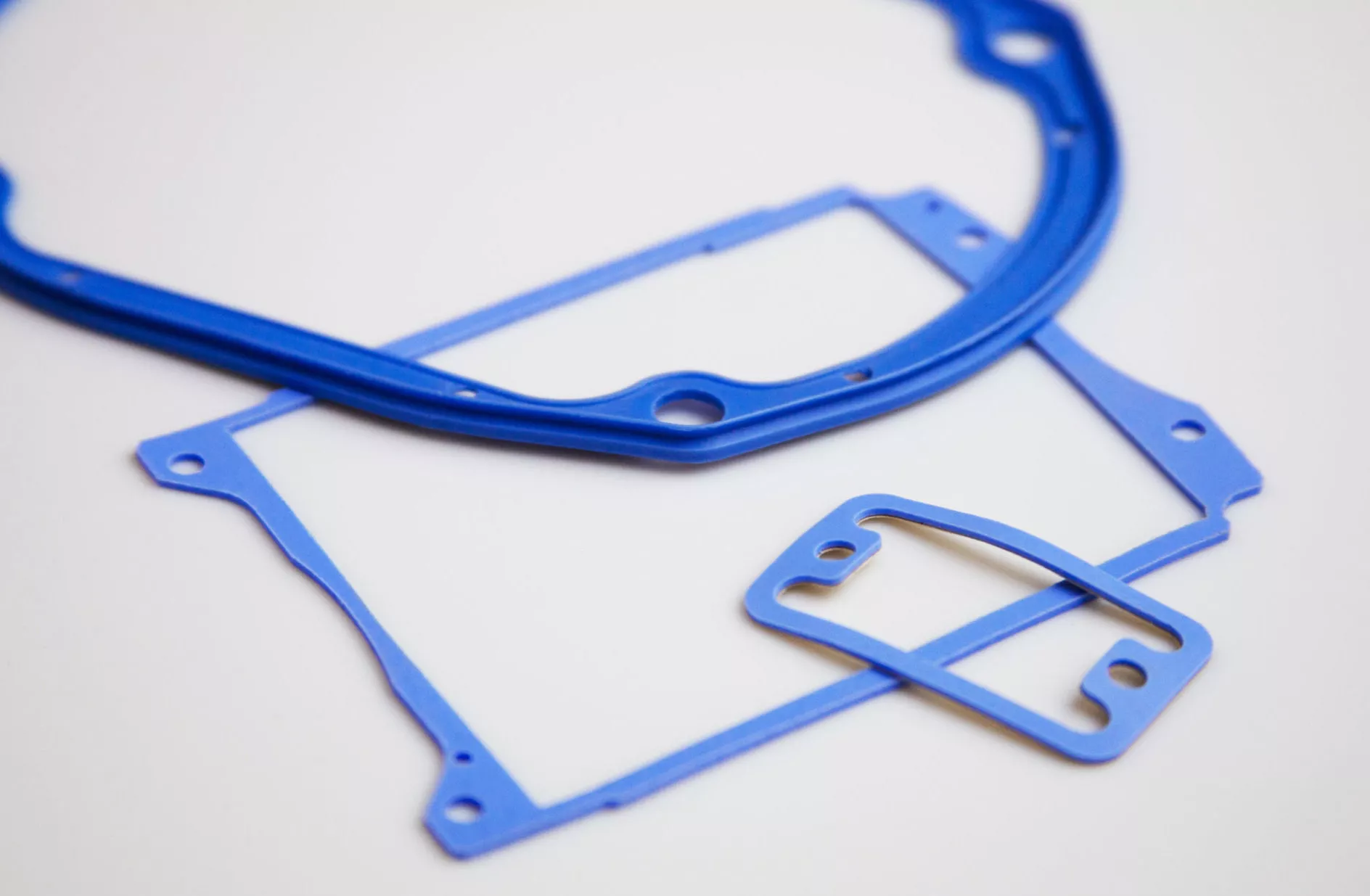

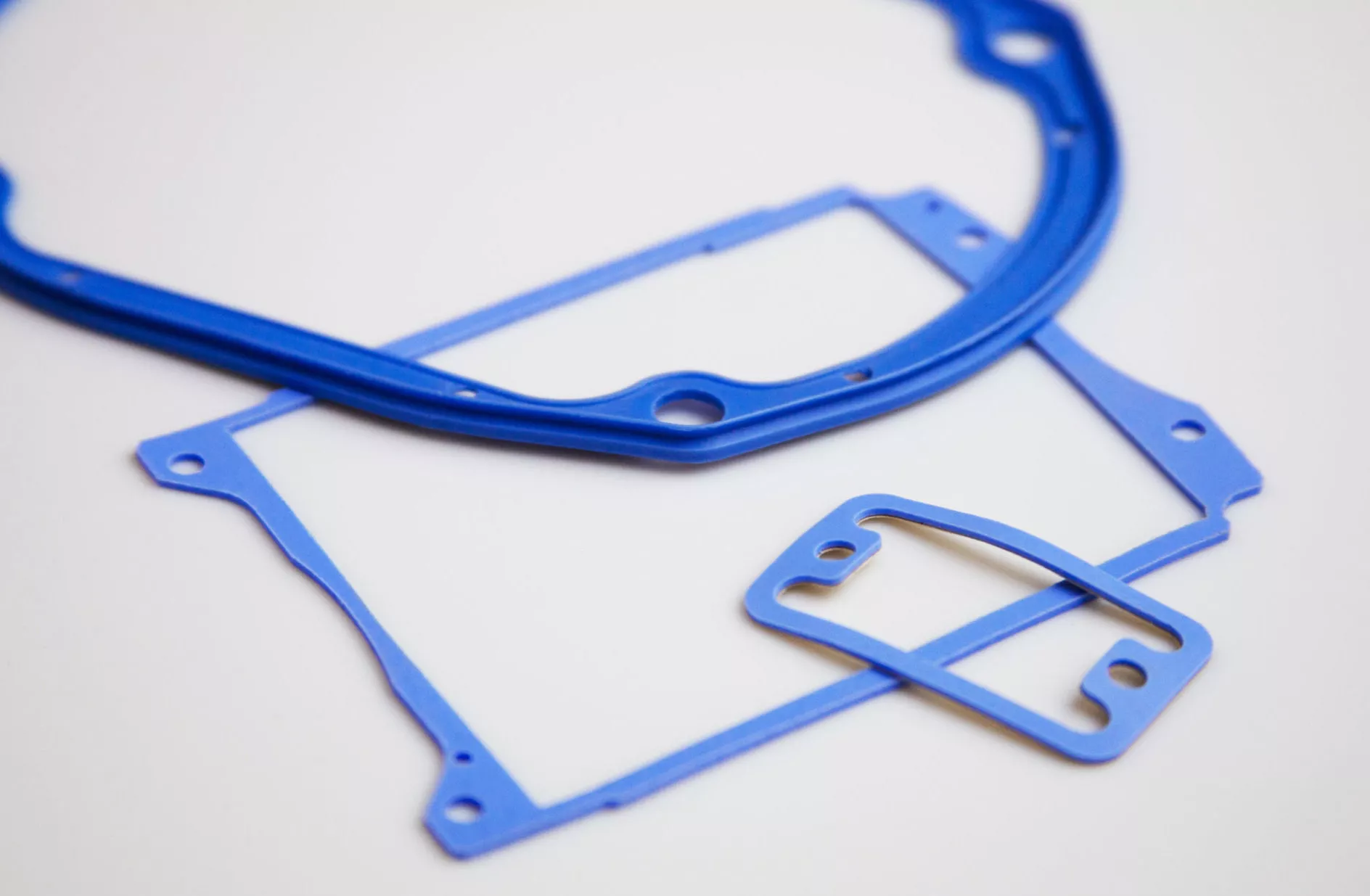

Ideal for multiple applications such as electronics and on-board systems, electronic management of brake controls and the finishing of business class seats.

| Properties | GT 70 E RF-2 | GT 70 M RF-2 | GT 70 E RF-4 |

|---|---|---|---|

| Density (g/cm3) | 1.35 ± 0.05 | 1.35 ± 0.05 | 1.39 |

| Hardness shore A | 70 ± 5 | 70 ± 5 | 71 |

| Break resistance MPa | > 6 | > 6 | 8.2 |

| Tear strength kN/m | > 10 | > 10 | 34.1 |

| Elongation at break % | > 180 | > 180 | 376 |

| RDC after 70 hours at 150°C | < 50 | < 50 | < 50 |

| Continuous working temperature | -60 to +200°C (peak at 230°C) | -60 to +200°C (peak at 230°C) | -60 to +200°C (peak at 230°C) |

| Color | Customizable | Customizable | Customizable |

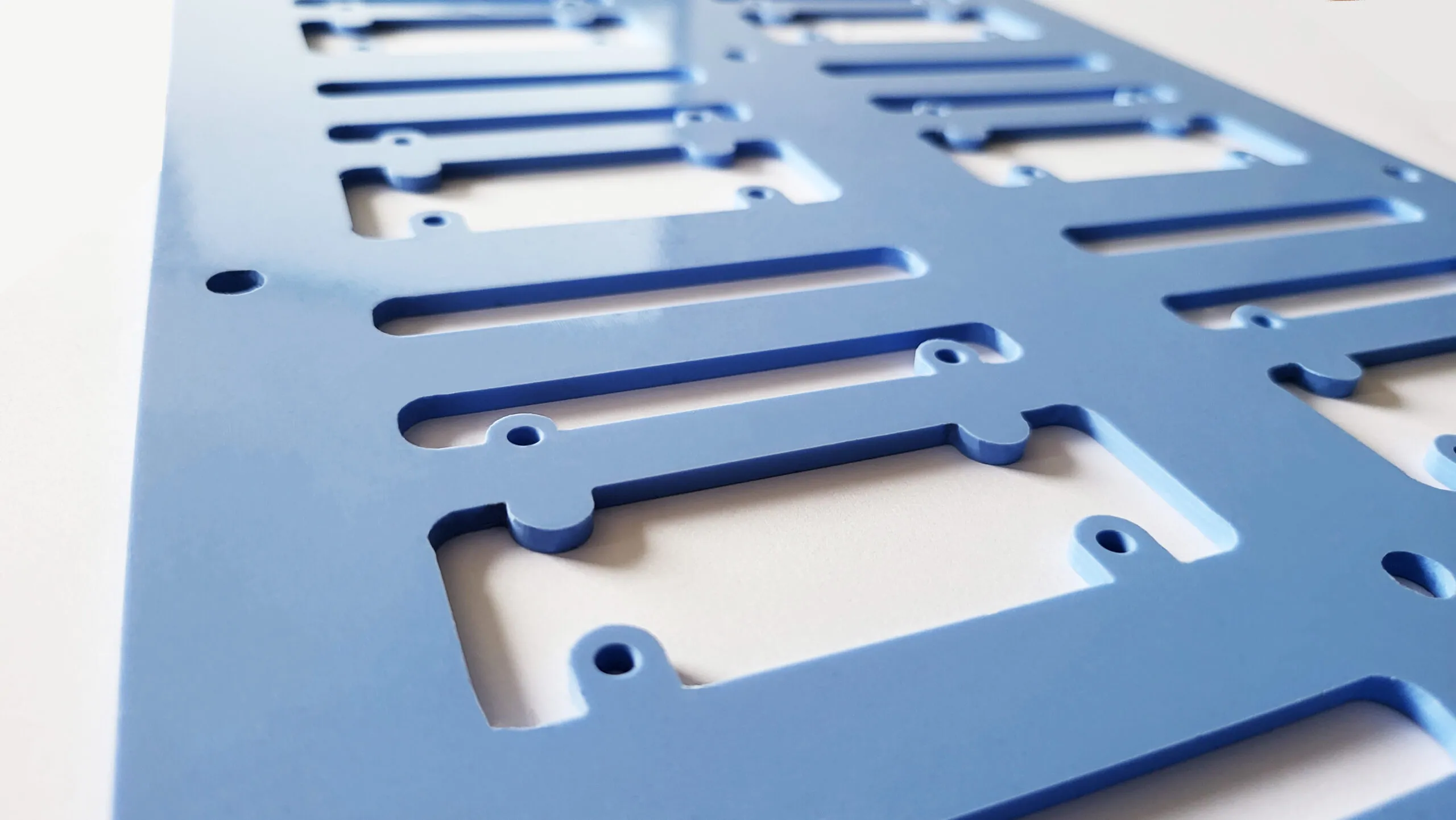

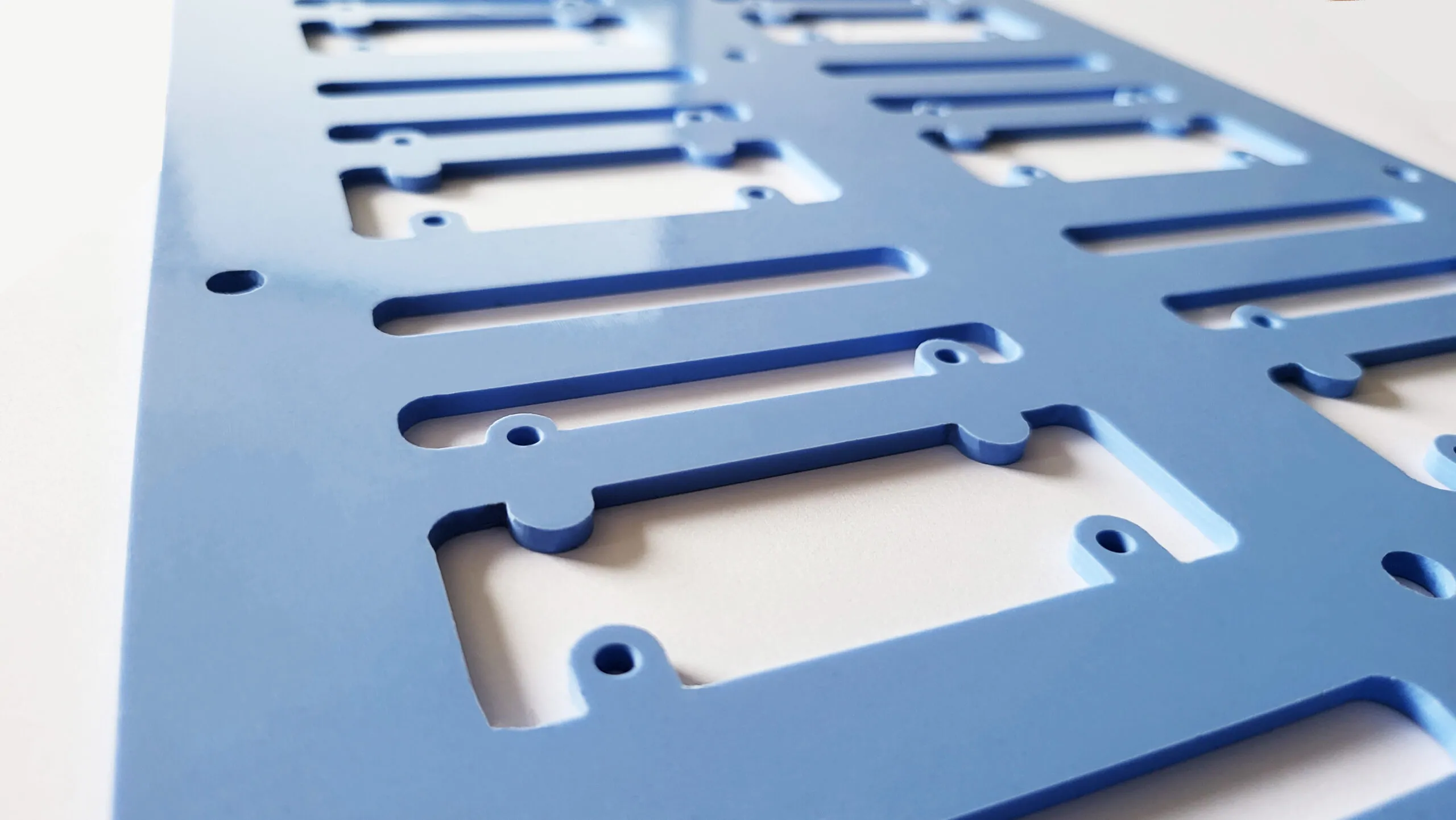

All of our products is available in standard format in the form of molded, cut, extruded or bespoke gaskets according to your plans.

We have more than 33 references of aeronautical quality mixtures made from different components such as:

Butadienne – Nitrile – Acrylic (NBR, Perbunan, Krynac, Hycar)

Fluorocarbons (Viton, Fluorel, Technoflon)

Fluorosilicone (FMVQ, silastic)

Silicone (VMP, PVMQ, Silastic, Rhodorsil)

Ethylene-Propylene EPDM

Polychloroprene – Neoprene